It’s hard to believe this month is December and this year is almost over. In the blink of an eye, we’ll be ringing in the New Year and meeting 2018 with new resolutions, goals and business objectives. For many in the industrial industry, those goals revolve around increasing OEE, creating better manufacturing processes, and generating more volume and more revenue.

That’s why your manufacturing facility needs to implement diamond-like carbon coatings in your 2018 budget - it’s going to help you reach those goals. How? I’m glad you asked.

1. Spend Less Time on Maintenance & Cleaning

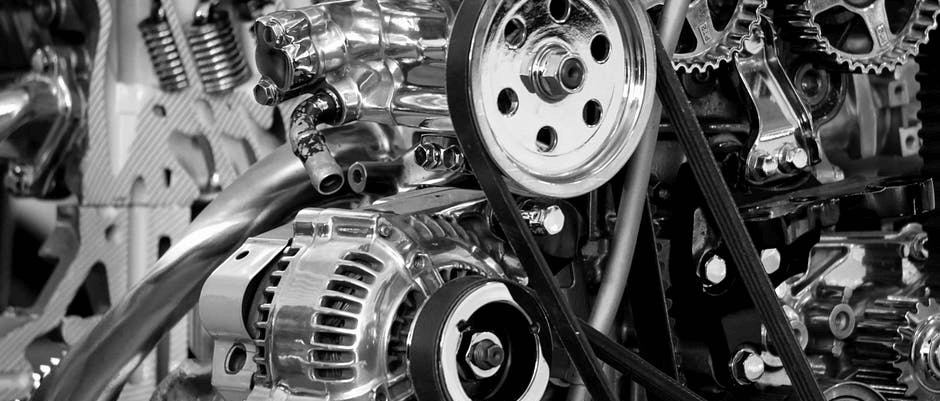

Think about how much time it takes for your team to take apart machinery to clean and inspect each of its intricate parts. Of course you have to do this to ensure everything is working properly and to avoid any unscheduled downtime. Well, by coating your machine parts in diamond-like carbon, or DLC, you could safely reduce the need to schedule that maintenance.

DLC coatings have a high lubricity and are extremely wear-resistant, which keeps machine parts cleaner for longer. By coating in DLC rather than another thin film, you can keep your production line online longer with less of a need to take apart the machinery and lubricate the different components.

2. Get the Most Out of Your Equipment

The lifespan of a machine is directly dependant on what is being manufactured and how well the machinery is being taken care of. Replacing parts and a whole machine or production line is a hefty fee.

However, DLC coatings have a unique set of properties allowing you to get the maximum lifespan out of your equipment. If DLC is applied to clean machinery and parts, it can exponentially increase the life expectancy of each part.

Check out this infographic to learn more about the properties and how DLC delivers ROI compared to the initial cost: Budget Planning for 2018: DLC Delivers ROI [INFOGRAPHIC]>>>

3. Operate More Efficiently

Overall Equipment Effectiveness, or OEE, is the calculation measuring the percentage of manufacturing time that is productive. In other words: Availability X Performance X Quality = OEE.

If the manufacturing process is slower than it could be, performance is lost. If the machinery isn’t running as efficiently as it could be to deliver the highest quality of products, the overall quality of product is compromised. And if production is disrupted due to any machinery malfunction, availability suffers.

DLC can improve OEE because it is extremely hard, it is highly lubricant, it’s corrosion resistant, it’s wear-resistant, it’s conformal to substrates, and it doesn’t lose any of its properties even with extreme operating temperatures.

Free eBook: The Manager’s Guide to Improving OEE in Your Industrial Facility

Enhance your manufacturing facility’s performance in 2018. Include DLC coatings in your New Year’s budget. And if you’re looking for more proof of DLC’s worth, download our free eBook now!